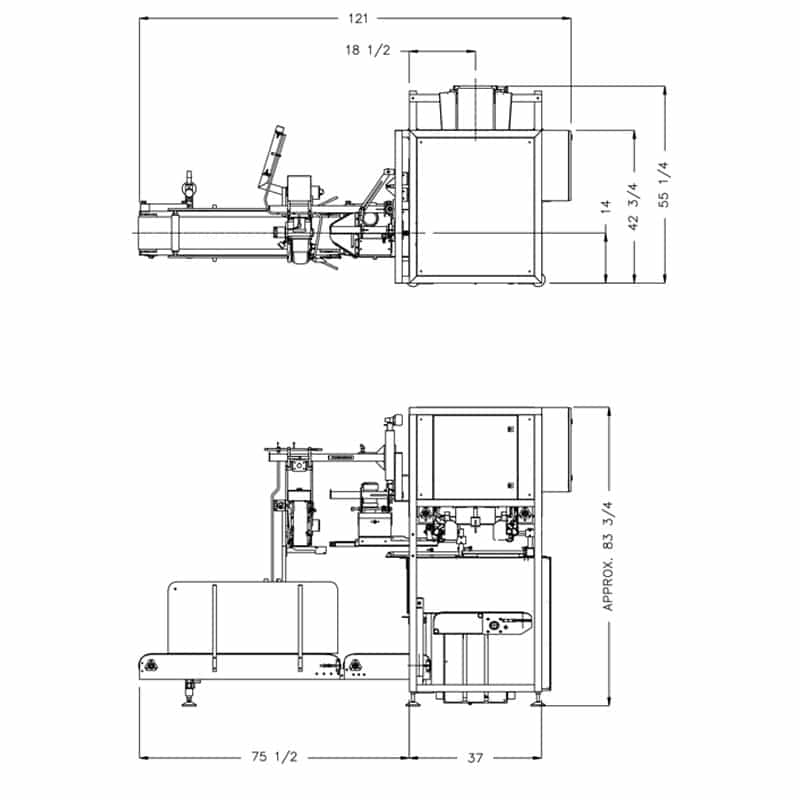

PB-50 Produce Bulk Bagger

Description

The JMC PB-50 Produce Bulk Bagger is a next generation automated bagging system. The PB-50 can open and fill all types of pre-made wicketted bags, including: poly, paper or mesh. The bagger will adjust to fill bags of varying sizes, and can be interfaced with most product portionning devices such as automatic scales, counters etc. The filled bag is automatically presented along the takeaway conveyor into the optional Fuseaire 4 Hot Air Sealer, integrated sewing head, or other types of closing devices.

Video

Specifications

POWER: 230 volt 3 PH. 60 Hz

AIR: 8 CFM @ 80 PSI

CAPACITY: 25 to 50 lbs.

APPROXIMATE SHIPPING WEIGHT: 1200 lbs.

Download

Download PDF Brochure for the PB-50 Produce Bulk Bagger.

Features

- OMRON P.L.C. with ethernet IP and touch screen

- Bilingual menus

- Epoxy coated painted frame

- Adjustable bag wicket

- Works with poly, paper and mesh bags

- Integrated “hands-free” feeding to closing device

- Bag Sense, “no bag, no dump”, ensures bag is in place avoiding spills

- NEMA 4 electrically certified control panel with dual channel safety

- Motorized Bag Saddle Conveyor (150 fpm)

- High speed intermediate takeaway conveyor with bag top transfer and feeding device

- High speed bag support conveyor

- Powered conveyor and chute for product delivery to bag

- 1 year limited product warranty on parts

Benefits

- Saves on manual labour

- Fully automatic

- Fast bag changeover

- Proven technology and reliable performance

- Customizable to suit multiple applications & bag types

- Machine sets bagging pace

- Fast ROI payback

Options

- JMC FuseAire 4 Hot Air Sealer(trimmer available)

- Fully integrated “swing away” sewing head option

- JMC Bag Kicker with longer T.A.C. to accommodate palletizer

- Mobility Kit

- Spare Parts Kit

- Stainless Steel Construction

Applications

- Produce