Adjustable Automatic Master Potato Baler

Description

The JMC Adjustable Automatic Master Potato Baler is an automated bagging system which gently counts, accumulates and packs pre-packaged bags into Master poly and paper bale bags. Also, aptionally into Mesh masters. Once filled the Master Bags are automatically moved via a conveyor in an upright position to be closed/sealed.

The system can be interfaced with the optional JMC FuseAire4 hot air sealer to close poly masters or with the optional integrated sewing head option for paper masters. It can also be integrated with most automatic closing devices and is compatible with all product bag types over from poly to paper Master Bags in minutes. The JMC “Space Saver” Incline Conveyor provides a compact footprint and the optional “Automatic Bypass” makes it ideal for loose stacking into bin boxes, RPC’s or re-routing product to an alternate process without the need to move or re-configure equipment.

The system handles potato bags ranging in size from 3 lbs to 20 lbs.

Video

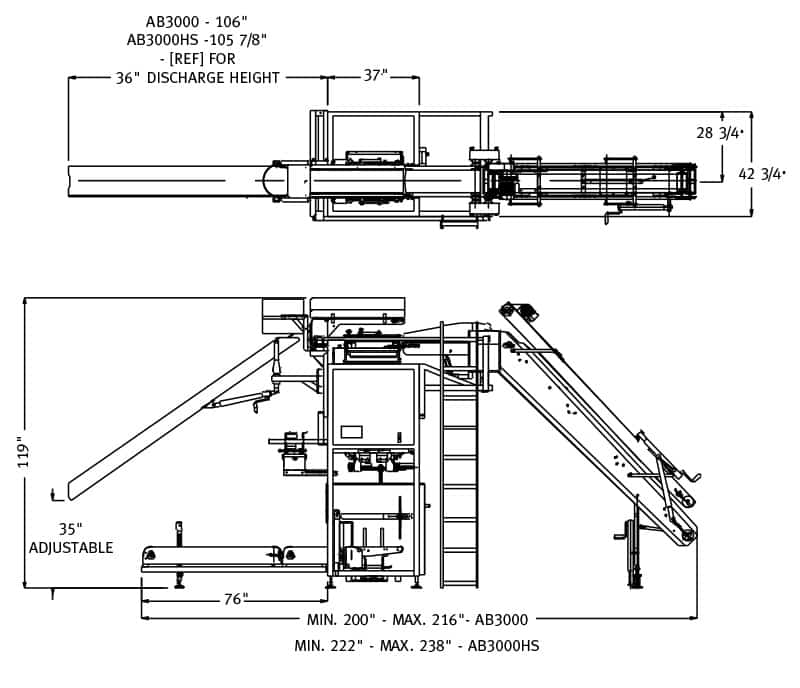

Specifications

POWER: 230 volt 3 PH. 60 Hz

AIR: 10 CFM @ 80 PSI

APPROXIMATE SHIPPING WEIGHT: 2700 lbs.

Download

Download PDF Brochure for the Adjustable Automatic Master Potato Baler.

Features

- OMRON P.L.C. (programmable logic controller)

- User Friendly Touchscreen

- Infeed mechanism & discharge gates

- Bale pusher with bag transport grippers

- Bag Sense “no bag, no dump”

- Bag inflation system

- Two way adjustable accumulating chamber

- Handles 3 – 20 lbs product bags

- Works with poly and paper master bags

- Accelerator conveyor assembly with JMC Space Saver Incline

- Product decelerator to eliminate bounce and prevent product damage

- NEMA 12 electrical “swing-away” control panel with interloc

- Motorized Bag Saddle Conveyor (150 fpm)

- High speed intermediate take away conveyor with horizontal alignment

- One year limited warranty

Benefits

- Master Bags are filled more gently than hand baling with JMC’s specially designed padding, air cylinder dampening and computer controlled deceleration

- Fully automated with “hands-free” closing to help save on manual labor

- Bag Sense ensures Master Bag is in place (and open) before releasing the product bags

- Filled bags are positively controlled to avoiding spilling

- Uniform Master Bags ensure easier palletizing, saving warehouse space

- Dependable, easy to use controls ensures minimum downtime & a short operator learning curve

- Proven technology with over 500 Master Balers currently in operation

Options

- JMC Autofeed Mesh Bale Bag Placer

- Automatic Bypass System with access ladder, bypass conveyor & discharge chute

- Warning systems

- JMC FuseAire 4 Hot Air Sealer(trimmer available)

- Takeaway guides (front and rear)

- Integrated sewing system

- Bale kickers

- Spare Parts Kit

- Turnkey robotic palletizing systems

Applications

- Potatoes

- Onions

- Other