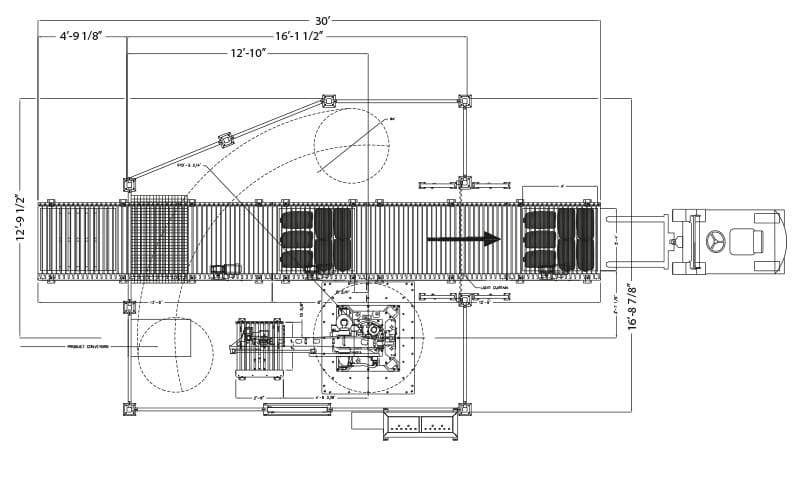

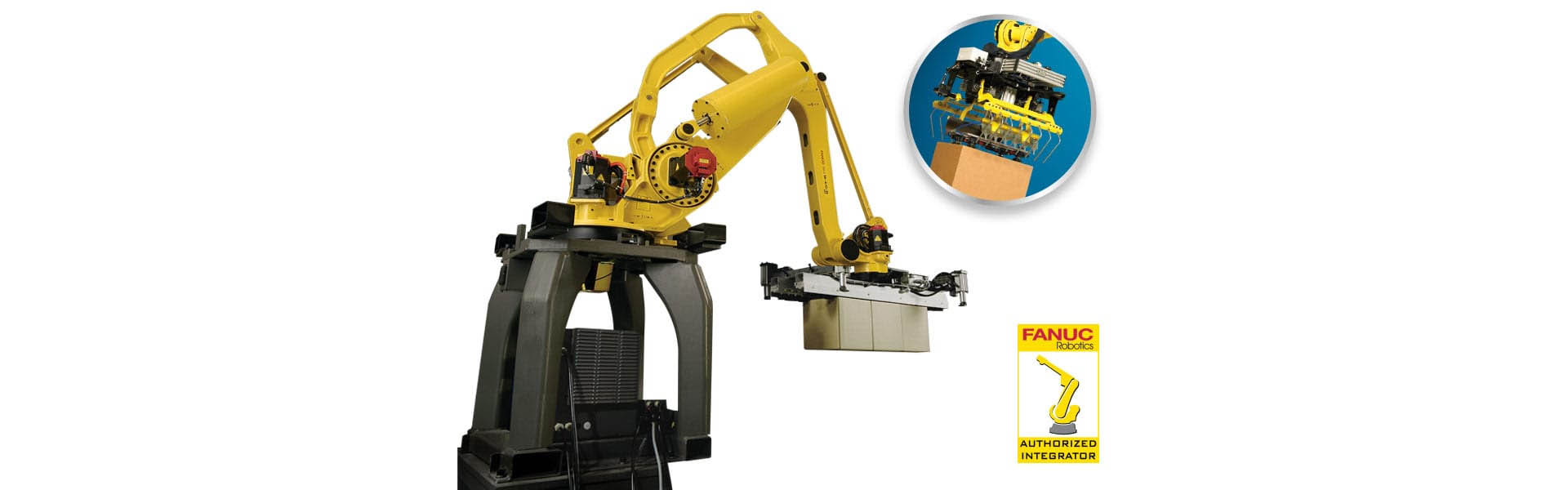

Robotic Palletizing System

Description

All JMC Palletizing Systems feature Fanuc Articulated Robot Arms, engineered for precision high-speed/high payload operation while providing the highest level of reliability and operational uptime. All JMC palletizing systems are customized and offered turn-key, including: design services, installation, set-up and training.

Specifications

POWER: 230/460/550 volt 3 PH. 60 Hz (min. 208 V)

AIR: 4 CFM @ 80 PSI

CAPACITY: Volumetric-adjustable up to 10lb maximum per dump

APPROXIMATE SHIPPING WEIGHT: 1200 lbs.

Download

Download PDF Brochure for the Robotic Palletizing System.

Features

- FANUC Robotics M-410iB/160 robot

- FANUC Robotics R-J3iC controller

- Teaching i-pendant

- Engineered end of arm tool

- Pick up conveyor

- OMRON P.L.C. (programmable logic controller)

- OMRON 8″ color touchscreen for easy menu driven selection

- Safety cell enclosure, powder coated epoxy

- Full safety compliant to ANSI/RIA safety requirements

- Comprehensive training package

- Systems integration and robot programming

- One year warranty

Benefits

- High reliability – Servo motor driven operation

- Maximum uptime – Over 65,000 hours documented between failure, plus collision guard software

- Low operating costs – Scheduled maintenance requires simply a grease change

- Customer support – Available 24/7 from FANUC Robotics at 800-47ROBOT

- After sales service – System fully designed in and supported from North America, real time in English

- Consistent pallets – Highly precise movement

- Flexibility – Can handle multiple infeeds and outfeeds

- Non-redundant – Easily adaptable to fit changing needs

Options

- Custom end of arm tooling

- Automatic pallet dispenser

- Automatic slip sheet placement

- Bag kickers

- Custom infeed & pallet conveyor packages

- Automatic stretch wrappers

- Check weighers

- Metal detection

Applications

- Bags

- Cases

- Pails